Manometer 2 click carries the MS5525DSO-SB001GS digital pressure sensor, based on leading MEMS technology. The click is designed to run on a 3.3V power supply. It communicates with the target microcontroller over I2C or SPI interface.

MS5525DSO-SB001GS features

The MS5525DSO-SB001GS is a new generation of Digital Small Outline pressure sensors with SPI and I2C bus interface designed for high volume OEM users.

The sensor module includes a pressure sensor and an ultra-low power 24-bit ?S ADC with internal factory calibrated coefficients. It provides a 24-bit digital pressure and temperature value and different operation modes that allow the user to optimize for conversion speed and current consumption.

The MS5525DSO-SB001GS consists of a piezo-resistive sensor and a sensor interface IC. The main function of the MS5525DSO-SB001GS is to convert the uncompensated analog output voltage from the piezo-resistive pressure sensor to a 24-bit digital value, as well as providing a 24-bit digital value for the temperature of the sensor.

How it works

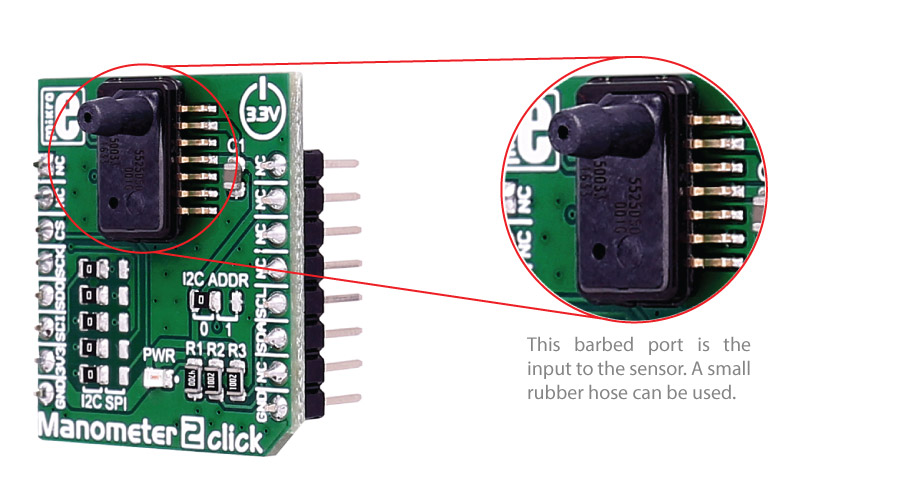

Manometer 2 click measures absolute pressure of 1PSI max, trough the barbed port.

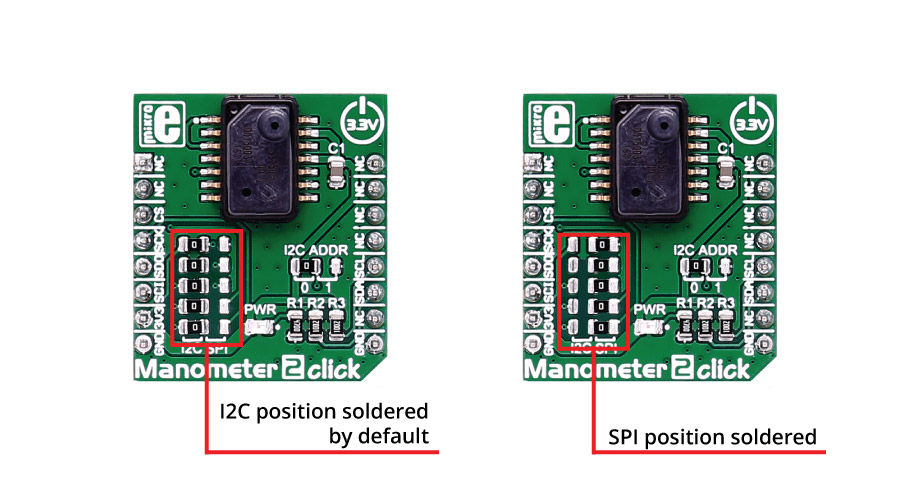

You can choose between SPI and I2C communication.

Specifications

| Type |

Pressure / Altitude |

| Applications |

Factory automation, altitude and airspeed measurements, medical instruments, leak detection, etc. |

| On-board modules |

MS5525DSO digital pressure sensor |

| Key Benefits |

24-bit digital pressure and temperature value |

| Interface |

I2C,SPI |

| Power Supply |

3.3V |

| Click board size |

S (28.6 x 25.4 mm) |

Pinout diagram

This table shows how the pinout on Manometer 2 click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  | Pin | Notes |

|---|

|

NC |

1 |

AN |

PWM |

16 |

NC |

|

|

NC |

2 |

RST |

INT |

15 |

NC |

|

| Chip Select |

CS |

3 |

CS |

TX |

14 |

NC |

|

| SPI Clock |

SCK |

4 |

SCK |

RX |

13 |

NC |

|

| SPI Master Input Slave Output |

MISO |

5 |

MISO |

SCL |

12 |

SCL |

I2C Clock |

| SPI Master Output Slave Input |

MOSI |

6 |

MOSI |

SDA |

11 |

SDA |

I2C Data |

| Power supply |

+3.3V |

7 |

3.3V |

5V |

10 |

NC |

|

| Ground |

GND |

8 |

GND |

GND |

9 |

GND |

Ground |

Jumpers and settings

In order to set the SPI interface, you need to move all the 5 jumpers (JP1-JP5).

These jumpers are soldered in I2C interface position by default.

There is an option to select the alternate address with jumper J6 in the case of I2C interface (default position is logic 0).

Programming

Code examples for Manometer 2 click, written for MikroElektronika hardware and compilers are available on Libstock.

Code snippet

The following code snippet shows the Manometer 2 click example, which takes care of initializing peripherals and the device, and then outputs the current pressure and temperature every 2 seconds.

01 void systemInit()

02 {

03 UART1_Init(9600);

04 Delay_ms(100);

05 UART1_Write_Text("nrInitialization...nr");

06 I2C1_Init_Advanced(100000, &_GPIO_MODULE_I2C1_PB67);

07 Delay_ms(100);

08 MMETER2_initDriver(pp001GS ,I2CAddress, I2C1_Start, I2C1_Write, I2C1_Read);

09

10 }

11

12 void main()

13 {

14 char uartText [60];

15 float measureResult;

16 systemInit();

17 UART1_Write_Text("Initializednr");

18

19 while( 1 )

20 {

21 measureResult = MMETER2_getTemperature(CONVERT_4096);

22 sprintf(uartText, "Temperature is: %3.3f Celsiusrn", measureResult);

23 UART1_Write_Text(uartText);

24

25 measureResult = MMETER2_getPressure(CONVERT_4096);

26 sprintf(uartText, "Pressure is: %3.3f PSIrnrn", measureResult);

27 UART1_Write_Text(uartText);

28

29 Delay_ms( 2000 );

30 }

31

32 }